Midsole Guide

This article will outline the major aspects of the most important component of modern running shoes, the midsole. We will focus on 4 distinct features of the midsole; foam, stability, heel drop, and plates.

Key Links:Foam

The first and arguably most important aspect of running shoe midsoles is their shape and feel, these qualities are largely in part due to the foam being used.

Which midsole foam is being used varies heavily between brands and even within brands, however, all foams share the trait of being composed of some sort of plastic. The 2 most common groups of midsole foam are EVA and PEBA. We will now go further in-depth for each and discuss when each of these foams is used and why.

Resource Links

EVA

Pros:- Durability

- Cost

- Responsiveness

- Weight

The original and most common midsole foam. This is the cheapest to produce and provides decent comfort. You will find EVA midsoles in everything from casual shoes to high-end running shoes (albeit, in a higher-quality formulation). It's very fair to say the EVA-based midsoles are THE midsoles for daily training. Daily trainers are supposed to be cost-efficient shoes that provide a good running experience for hundreds of miles. EVA midsoles are what enable that. The foam is not the softest, not the bounciest, not the lightest, but it is cheap, comfortable, and durable. To get more out of EVA midsoles many brands have begun blending EVA with other plastics:

- Asics with FF Blast+: EVA + OBC midsole is extra bouncy but it lacks durability.

- Saucony with PWRRUN+: EVA + TPU midsole that is a little heavier but has great impact absorption and extra durability.

- New Balance with FuelCell: EVA + PEBA midsole that is super light and responsive but lacks durability and stability.

Super critical EVA

This subset of EVA foam is made during the midsole molding when the EVA is injected with a gas (Nitrogen or CO2). The result is a lighter and more responsive foam. Thus some brands utilize supercritical gases to produce more fun and higher performance foams as an alternative to their regular EVA midsoles.

- Hoka with the Mach line: The Mach 5 and Mach 6 incorporated supercritical EVA to increase the responsiveness of their top training shoe.

- Brooks and DNA Loft: Brooks DNA Loft midsole involves incorporating nitrogen-infused supercritical EVA to keep their shoes light and bouncy.

PEBA

Pros:- Lightweight

- Responsive

- Keep legs fresh

- Durability

- Price

- Stability

PEBA is the main component in the midsole of every high-performance running shoe. Since the notorious 2016 Rio Olympics where Nike athletes dominated the marathon, it became apparent that PEBA midsoles are a must for unlocking a runner's full capabilities. The foam has the unique property of being extremely lightweight and extremely responsive (energy efficient). In general EVA midsoles return 70 to 75% of a runner's energy on each stride, for PEBA that number goes up to 90 to 96%. Throughout the race, the benefits can be dramatic.

While traditionally reserved for ensuring optimal performance on race day, PEBA foam midsoles have slowly crept their way into the training shoes of many brands. While lacking durability, the use of PEBA provides an elevated training experience, both in performance and recovery. These "super trainers" often have midsoles that are a blend of EVA and PEBA to strike a delicate balance between the pros and cons of each foam (which you should know from reading this article).

Stability

Stability shoes refer to the subset of running shoes that have added elements meant to counteract the inward roll of the ankle. This inward roll is referred to as over-pronation and is a common issue which runners (and walkers) with flatter feet. These stability elements prevent overpronation by guiding the runner's foot as it rolls from heel to toe. Throughout the history of running shoes stability elements varied drastically, however, in recent years there has been a convergence towards a few necessary elements which provide a great stable experience.

Foam Density

I find it helpful to compare stability shoes to an equivalent neutral model from the same brand. Some examples include; Asics Gel Kayano 30 vs Nimbus, New Balance 860 vs 880, and Hoka One One Arahi 7 vs Clifton. One common trait that almost every stability shoe possesses over the neutral model is a higher density, and thus more stable, foam. The purpose of this foam is obvious, a less malleable and squishy foam provides greater resistance to the foot's overpronation. This higher-density foam can either make up the entirety of the midsole unit, or it can appear in a dual-density formation where the higher-density foam is tactically placed on the medial (innermost side) to increase the stability where runners need it most. Below is a list of common and effective examples of this feature.

- Asics Gel Kayano 30: Utilizes the 4D guidance system which is a pocket of high-density foam on the medial side of the midfoot.

- Saucony Guide 17: The entire midsole unit is made out of a more stable and dense foam than what you would find in Saucony's other running shoes.

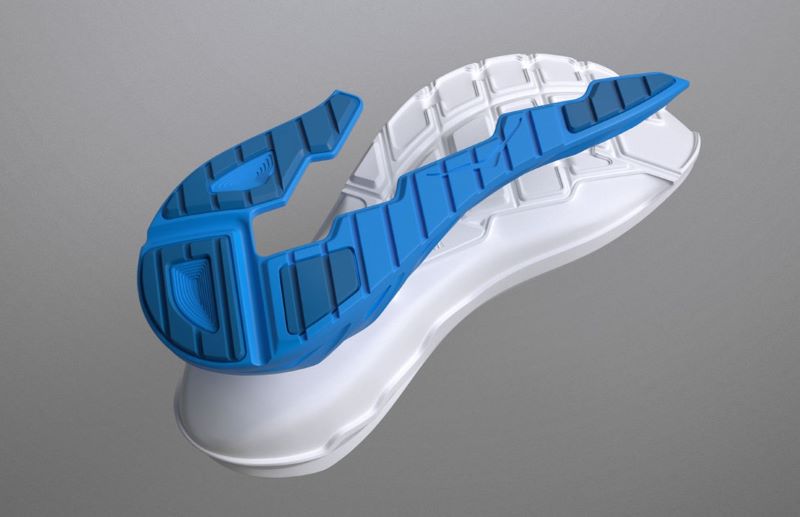

- Hoka One One Arahi 7: The Arahi utilizes Hoka's J Frame stability technology which, as the name suggests, is a high-density foam in the shape of a J throughout the midsole. The long part of the J covers the entire inner length of the midsole until it cups the heel on both sides.

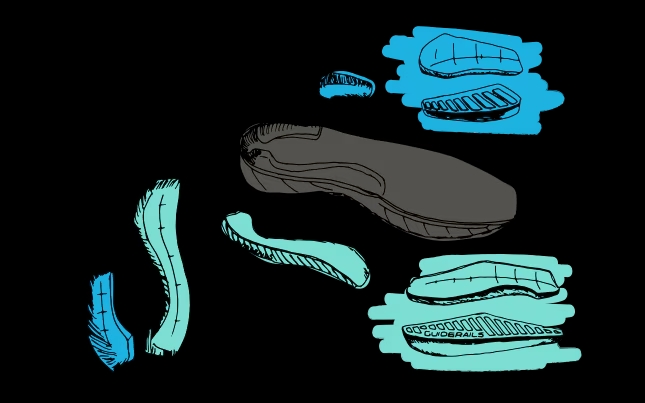

Guard Rails

Another useful stability element present in most if not all stability shoes is the guard rails. Guard rails refer to the vertical extension of the midsole both on the lateral (outer) side and the medial (inner) side of the heel-to-midfoot region. Remember the goal of stability elements is to guide the runner's foot gait. Guard rails help achieve this by cupping the foot and providing resistance to pronation on either side. This is a wonderful way of providing stability while minimizing the changes made to the underfoot sensation of the midsole.

- Asics GT-2000 and Kayano: Both of these Asics stability shoes have prominent vertical guard rails extending from the midsole to enhance the stability of the shoe.

- Brooks Go-To Support (GTS): Brooks is a little different as they add stability elements to their otherwise neutral shoes in the form of guard rails. The rails are prominent and provide an unintrusive, stable experience.

Although it has nothing to do with midsoles I have to mention heel cups here. Heel cups are usually a plastic or tighter knit/nylon material around the heel of many running shoes. Since pronation can start at the heel this element is a common method of providing stability early in the foot gait. Its functionality and placement are akin to the guard rails so I thought it would be appropriate to mention it here.

Wide Bases

The final stability element I will talk about has only recently become a popular feature in most stability shoes. Anyone who has been paying attention to running shoes has noticed that in in recent years, midsole units have gotten bigger. It is my understanding that recent advancements in foam technology have allowed for the creation of foam compounds that are lighter and more comfortable. This means modern running shoes have a much higher foam-to-weight ratio which makes them more comfortable and better at keeping your legs fresh after a workout.

The benefits of more foam under your foot are evident, however, as we learned in science class a tall structure with a narrow base is inherently unstable (not the CN Tower though, that shit's goated). This explains the need for a new stability element, a wide midsole, which provides a more stable base for the modern running shoe. There isn't much else to say about this stability element. Some shoes will mostly increase the base in the heel and forefoot while others will extend the platform throughout the entire shoe. While this stability element isn't everyone's cup of tea (due to it making shoes less agile, and heavier weight) it looks like the future for most running stability shoes.

- Saucony Guide 17: In the latest iteration of the Guide Saucony has drastically increased the width of the midsole from the heel to midfoot. Saucony describes this as "[a]nti-rollerover technology with a wider, more stable chassis".

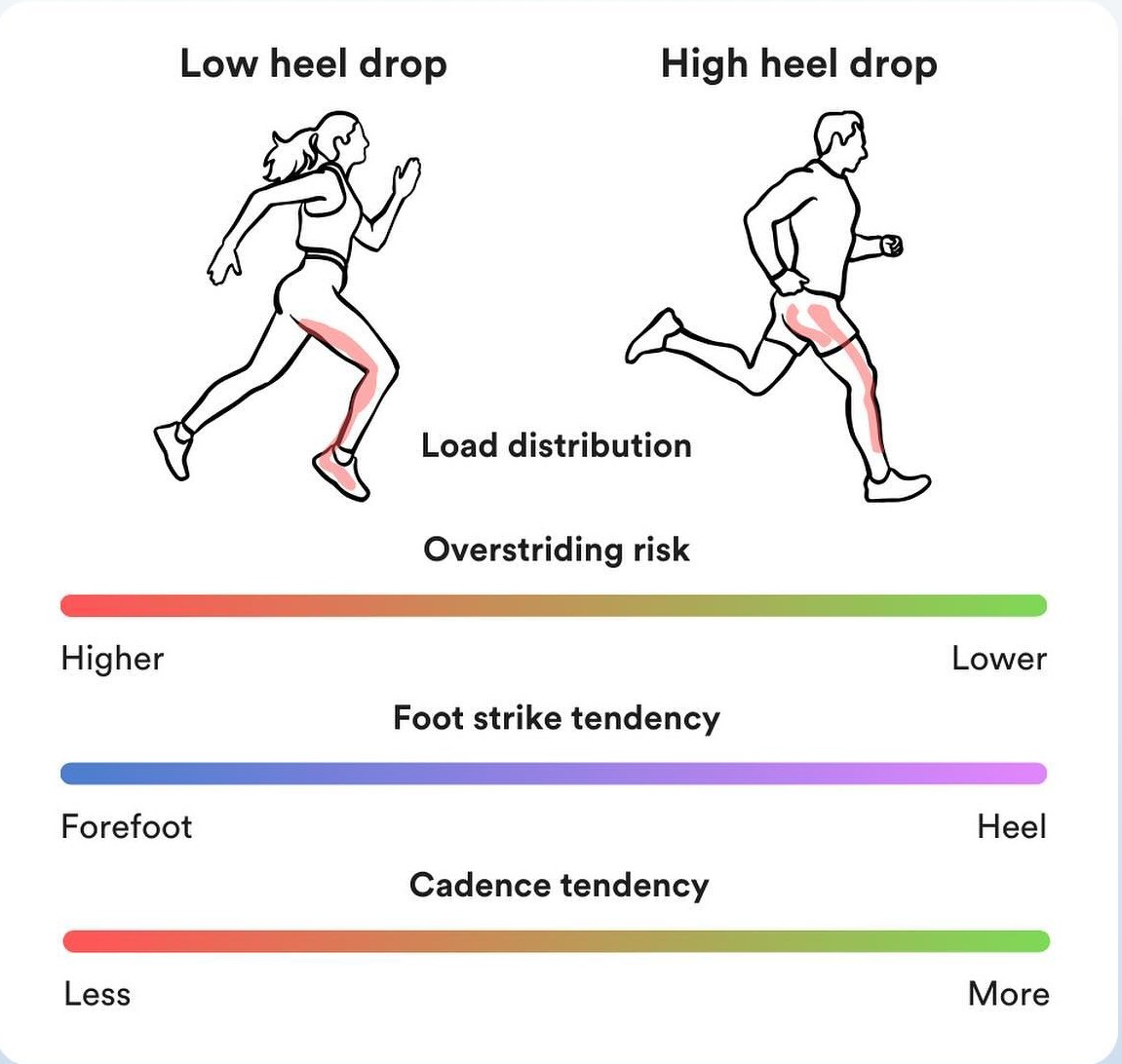

Heel Drop

Another key aspect of the midsole is the heel drop. This refers to the offset in stack height between the heel and the forefoot. The importance of the heel drop is that it dictates how the foam is distributed, and how much effort it takes for the shoe to roll from heel to toe. For a runner that strikes with their heel, a larger drop (10-12mm) will be beneficial. This is because there is relatively more cushioning in the heel (where they land) and the shoe will more effortlessly roll from the landing zone to toe-off. On the flipside, a forefoot striker would generally benefit from a lower drop (< 6mm) This is because a shoe with a lower drop provides relatively more cushioning under their landing zone and less weight in the heel which won't be used.

When it comes to walking almost everyone is a midfoot/heel striker. This means a large drop might make more sense for a walking shoe. However, heel drop is not the only factor to consider. The geometry of a midsole can increase the ease of roll from heel to toe. For example, Hoka's 'meta-rocker' technology allows their shoes with relatively low drops to roll easily.

Credits: jsncpp on Instagram

Plates

The final midsole element to talk about is carbon and plastic plates. The use of these plates helps runners and their shoes reach the upper limits of performance. The reasoning behind this is best examined when looking at the benefits a plate provides to foam, stability, and roll.

As mentioned previously PEBA midsoles are super-responsive allow runners to achieve maximum efficiency in their strides, however, the cost is stability. Remember, a wider base can add stability to a shoe but this isn't ideal when it comes to racing due to the added weight. Another solution for PEBA's inherent instability is the placement of a carbon plate throughout the midsole. This solution adds stability while minimizing extra and actually increases the efficiency of the shoe due to the plate. This is part of the reason why the rise of PEBA foams saw a rise in plated shoes, there needed to be a mechanism to add stability to the shoe while maintaining (or in this case improving) the responsiveness and keeping the weight low. This is why the rise of PEBA foams saw the rise of carbon plates, they were meant for each other.

Although I previously mentioned that a larger heel-to-toe drop promotes an effortless roll this logic can somewhat be ignored when it comes to carbon plates. Due to their stiffness and the angle at which they curve, carbon-plated shoes are the best means of decreasing the effort it takes for a runner to go from landing to toe off.

Plastic-based plates lack the same performance benefits as carbon plates but still provide benefits in a variety of PEBA-based training shoes. For example, Saucony's Endorphin Speed series utilizes a nylon plate within its PEBA-based foam. This provides the same benefits as their carbon-plated marathon shoe, in a tone-down and more cost-efficient package. You still get the stability and natural roll added to the PEBA midsole while maintaining its responsiveness.

Another example of plated shoes that aren't for race day is in the emerging group of running shoes known as 'super-trainers'. This category includes shoes that have many of the features of race shoes built into a training-oriented package. This means you get a heavier shoe that will last longer than a race shoe but still has a carbon plate and the presence of high-quality foam. Examples: